Recent Blogs

- Ready-to-Assemble Steel Structure to Sudan for the United Nations – Case Study

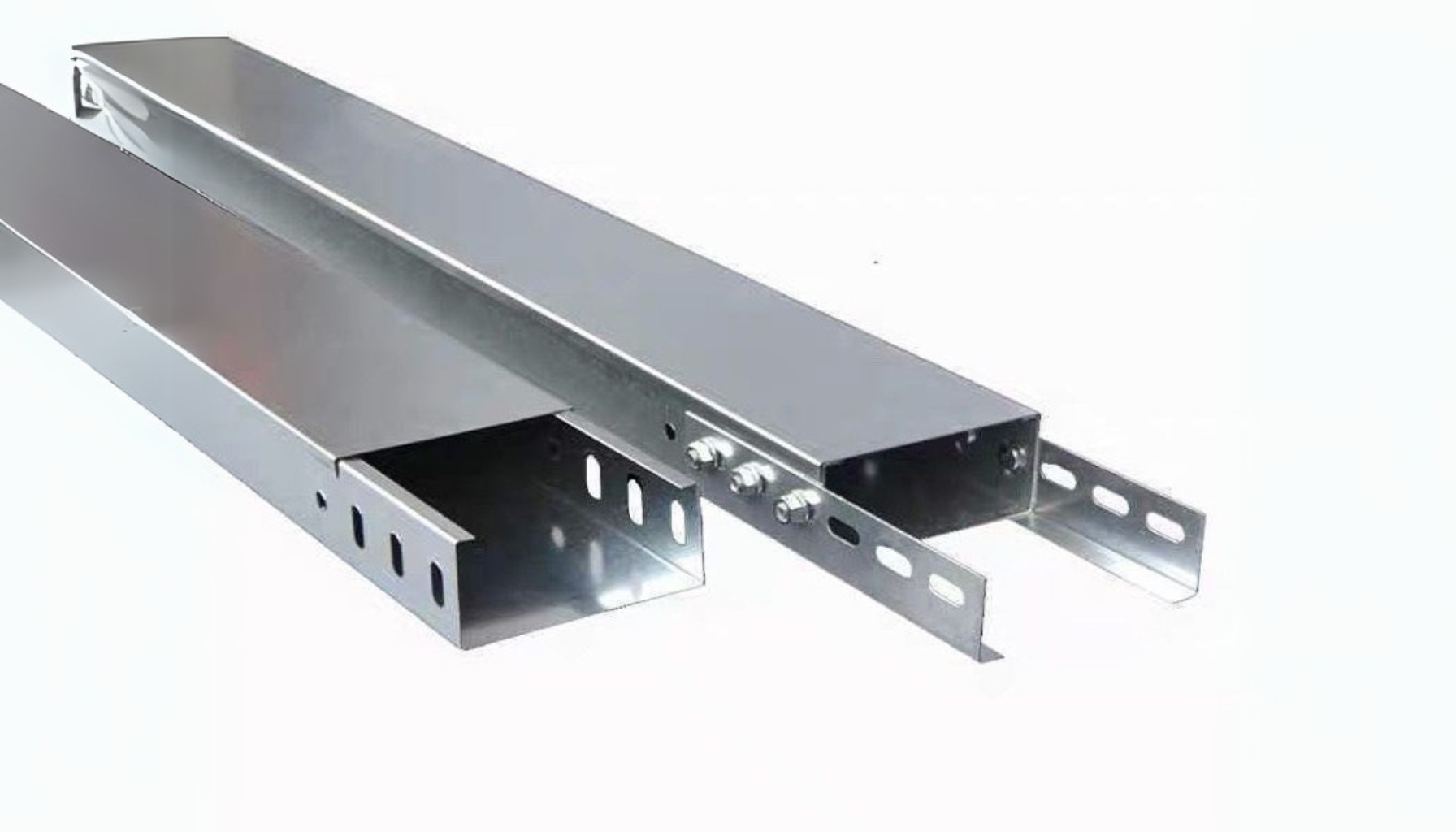

- Which Steel Cable Tray Type is Best? A Look at Perforated, Ladder, Wire Mesh & Flexible Trays

- The Impact of Temperature Variations on Cold Storage Warehouses in Different Cities of Uganda

- The Impact of Factory Shed Layout on Workflow Efficiency

- Uganda’s Rising Demand for Cold Storage Builders in the Logistics Industry