When it comes to efficient cable management, electrical cable trays are an indispensable solution in modern buildings and industrial facilities. Selecting the right material for a cable tray is crucial as it impacts durability, cost, installation, and long-term performance. Among the most common materials are aluminium, steel, and plastic. This article provides a detailed comparison of these materials, with a focus on why steel cable trays stand out as the superior option for most applications.

1. Overview of Electrical Cable Tray Materials

Aluminium Cable Trays

Aluminium cable trays are lightweight and corrosion-resistant, making them suitable for indoor and some outdoor applications. They are often used in environments where weight reduction is a priority.

Steel Cable Trays

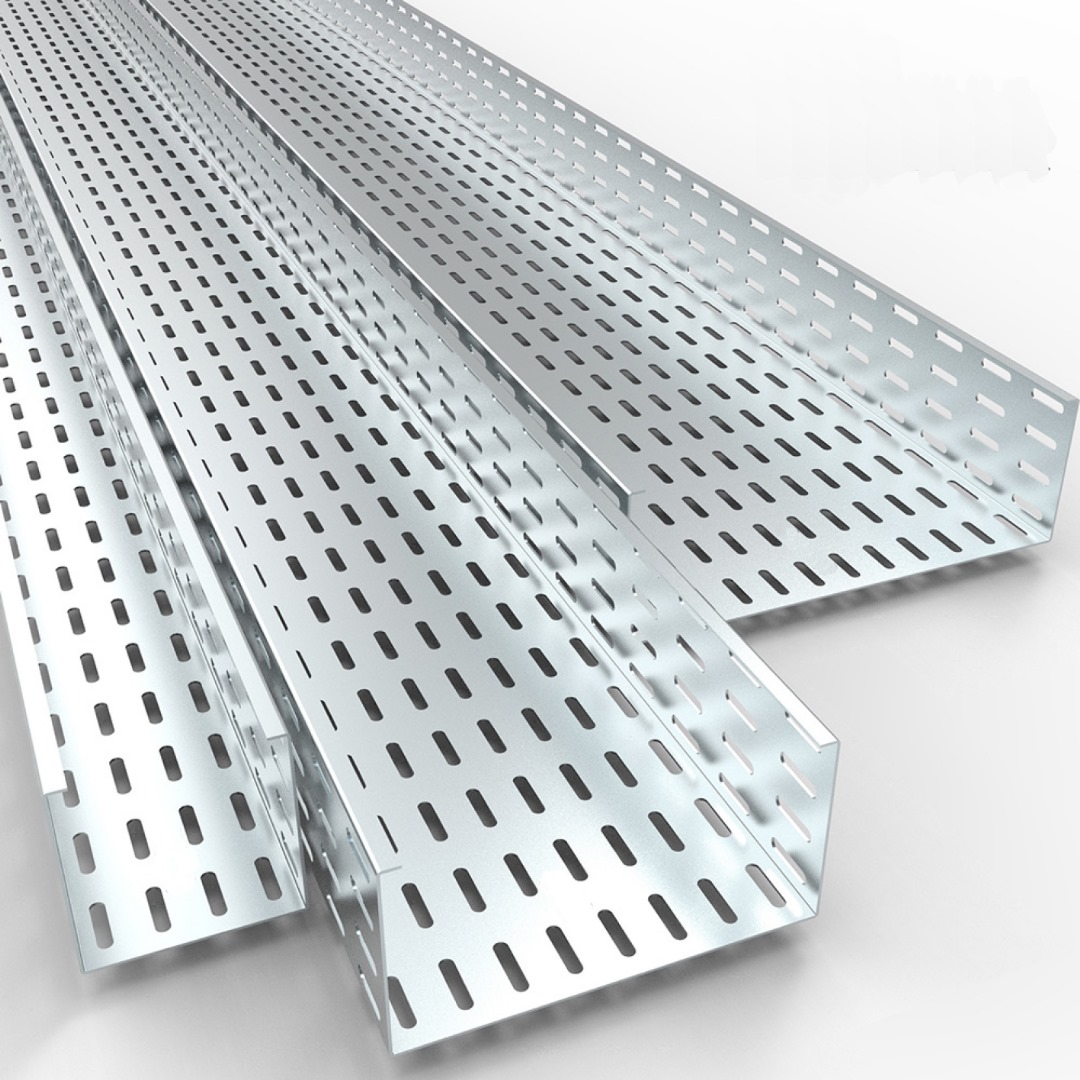

Steel is the most popular material for electrical cable trays due to its unmatched strength, versatility, and durability. Variants include stainless steel cable trays and galvanized steel cable trays, both of which are tailored to specific environments and requirements.

Plastic Cable Trays

Plastic cable trays, typically made from PVC, are known for their cost-effectiveness and resistance to chemical exposure. They are lightweight but lack the durability and strength of metal options.

2. Key Factors in Choosing Cable Tray Materials

Durability and Strength

- Steel Cable Trays: Steel is exceptionally strong, capable of handling heavy cable loads without bending or sagging. This makes steel fabricated cable trays ideal for industrial applications, data centers, and areas requiring robust support.

- Aluminium Cable Trays: While durable, aluminium lacks the same strength as steel and is prone to deformation under heavy loads.

- Plastic Cable Trays: Suitable for lighter applications, plastic trays cannot handle heavy cables or harsh mechanical stress.

Corrosion Resistance

- Stainless Steel Cable Trays (SS Cable Trays): These trays are highly resistant to corrosion, making them ideal for humid, coastal, or chemically aggressive environments.

- Galvanized Steel Cable Trays: The zinc coating provides protection against rust and corrosion, making them suitable for indoor and outdoor applications.

- Aluminium Cable Trays: Naturally resistant to corrosion but can weaken in highly acidic or alkaline environments.

- Plastic Cable Trays: Completely corrosion-proof but prone to degradation under UV exposure and extreme temperatures.

Cost Efficiency

- Steel Cable Trays: Despite a higher upfront cost, their durability and longevity make them cost-effective over time.

- Aluminium Cable Trays: More expensive than plastic but less costly than stainless steel. Ideal for lightweight applications.

- Plastic Cable Trays: The most affordable option upfront but less durable, leading to higher replacement costs.

3. Types of Cable Trays Available in Each Material

Steel Cable Trays

Steel is versatile and used to manufacture various cable tray types, including:

- Ladder Cable Trays: Perfect for heavy-duty industrial use, with open designs that facilitate airflow.

- Perforated Cable Trays: Offer ventilation for medium-duty applications.

- Wire Mesh Cable Trays: Ideal for lightweight, flexible installations in ceilings or under floors.

Aluminium Cable Trays

Commonly found as perforated cable trays and lightweight ladder cable trays, aluminium is less versatile than steel but serves well in specific environments.

Plastic Cable Trays

Plastic trays are typically limited to smaller-scale applications, such as flexible cable trays or floor cable trays for indoor use.

4. Advantages of Steel Cable Trays

1. Unmatched Load-Bearing Capacity

Steel cable trays are the preferred choice for applications requiring heavy-duty support. Whether used in industrial cable trays or data center cable trays, steel can bear large cable loads without warping.

2. Long Lifespan

The durability of galvanized steel cable trays and stainless steel cable trays ensures a longer operational life compared to aluminium and plastic alternatives. They are less likely to crack, deform, or degrade over time.

3. Versatility in Applications

Steel can be fabricated into a wide range of designs, such as hanging cable trays, ceiling cable trays, and mesh wire cable trays, catering to diverse installation needs.

4. Heat Resistance

Unlike plastic trays, steel can withstand high temperatures, making it suitable for electrical systems prone to heat generation.

5. Aesthetic and Professional Finish

Powder-coated or galvanized steel trays offer a clean, polished look for visible installations.

5. Limitations of Aluminium and Plastic Trays

Aluminium Cable Trays

- Cannot match the strength and load-bearing capacity of steel fabricated cable trays.

- Limited in terms of customization options.

- May incur higher costs for repairs or replacements in heavy-duty applications.

Plastic Cable Trays

- Lack durability, especially in harsh environments.

- Susceptible to damage from UV rays and extreme temperatures.

- Limited to light-duty installations, such as indoor flex cable trays.

6. Use Cases for Steel Cable Trays

1. Industrial Settings

Steel is the go-to material for industrial cable trays due to its ability to handle heavy power cables and withstand harsh conditions.

2. Data Centers

In data center cable trays, steel ensures stable and secure support for critical network and power cables. Perforated cable trays and wire cable trays in steel are commonly used for these applications.

3. High-Corrosion Areas

Stainless steel cable trays excel in environments with high humidity or exposure to chemicals, such as wastewater treatment plants or coastal facilities.

4. Overhead and Ceiling Installations

Hanging cable trays and ceiling cable trays in steel provide robust support for cables in warehouses, factories, and commercial spaces.

7. Factors to Consider When Choosing a Material

When selecting the best material for an electrical cable tray, consider the following:

- Cable Tray Sizing: Ensure the material can support the required cable load. Steel offers the best load-bearing capacity.

- Environmental Conditions: Use stainless steel cable trays for corrosive environments or galvanized steel trays for general outdoor use.

- Cost vs. Longevity: While steel may have a higher upfront cost, its long-term durability justifies the investment.

8. Comparing the Electrical Cable Tray Price

- Steel Cable Trays: Higher initial cost, but lower maintenance and longer lifespan make them a cost-effective choice.

- Aluminium Cable Trays: Moderately priced but less durable than steel.

- Plastic Cable Trays: The cheapest upfront but require frequent replacements, increasing long-term costs.

9. Conclusion: Why Steel Cable Trays Are the Best Choice

While aluminium and plastic cable trays serve specific needs, steel cable trays remain the superior choice for most applications due to their unmatched strength, durability, and versatility. Whether you’re installing cable trays for data centers, industrial settings, or overhead systems, steel provides the reliability and performance needed for safe and efficient cable management.

Read More Articles About Cable Trays

- Ready-to-Assemble Steel Structure to Sudan for the United Nations – Case Study

- Which Steel Cable Tray Type is Best? A Look at Perforated, Ladder, Wire Mesh & Flexible Trays

- The Impact of Temperature Variations on Cold Storage Warehouses in Different Cities of Uganda

- The Impact of Factory Shed Layout on Workflow Efficiency

- Uganda’s Rising Demand for Cold Storage Builders in the Logistics Industry