Walking through the heart of industrial progress, one often encounters a hidden hero working tirelessly behind the scenes: the stainless steel cable tray. A cable duct stainless steel is a critical component that silently supports the backbone of operations in some of the most demanding environments. From power plants humming with energy to pharmaceutical facilities crafting precision medicines, these cable trays ensure that essential wiring stays organized, protected, and efficient. Let’s journey into how different industries utilize these stainless steel wire cable trays.

Power Generation: The Lifeline of Energy Infrastructure

In power plants—whether thermal, hydro, or nuclear—reliability is non-negotiable. Imagine the miles of cables running through a nuclear power station, managing everything from reactor controls to safety systems. This is where the steel cable tray proves its worth. With its robust build, a stainless steel wire cable tray holds heavy electrical wiring securely in place, even under extreme temperatures or vibrations.

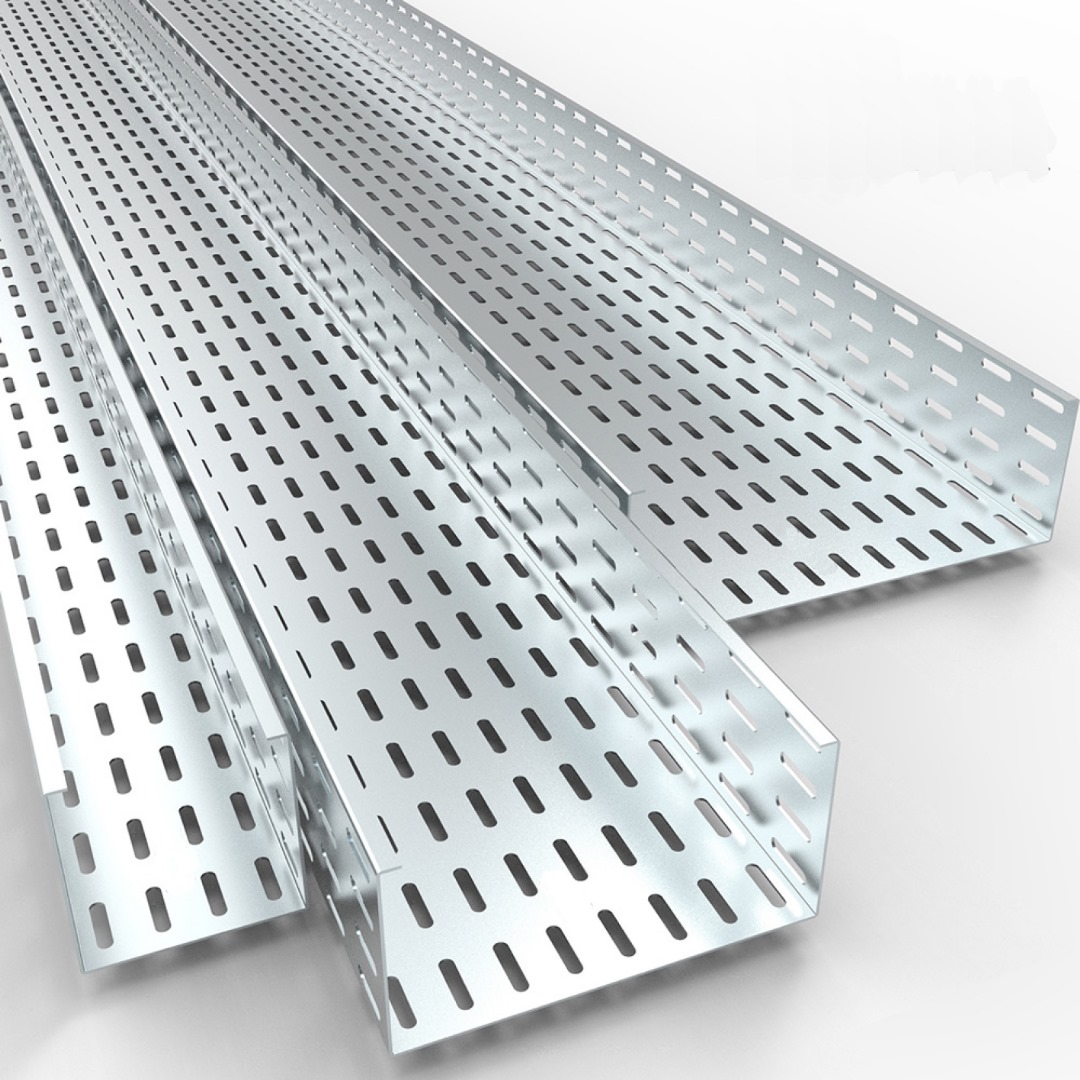

For these environments, ladder cable trays and perforated cable trays are popular choices. Their sturdy design ensures that power flows uninterrupted, even in high-stress conditions. By keeping wires properly ventilated and shielded, cable duct stainless steel minimize risks of overheating and electrical failures.

Oil and Gas: Enduring Harsh Offshore Conditions

The oil and gas industry operates in some of the harshest environments on Earth, from scorching deserts to corrosive offshore platforms. Here, a stainless steel wire tray is indispensable. Resistant to saltwater corrosion and chemical exposure, it ensures critical cables for drills and safety systems stay intact.

On offshore platforms, the compact and flexible design of a stainless steel basket tray is especially useful. It allows for easy installation in tight spaces while maintaining excellent airflow to prevent overheating.

Chemical and Petrochemical: Handling Corrosive Substances

Chemical plants and refineries are rife with corrosive elements that can wreak havoc on infrastructure. A stainless steel perforated cable tray is a reliable solution, offering robust protection against chemical exposure while ensuring proper cable ventilation.

The ability to withstand high temperatures and corrosive materials makes stainless steel a preferred material in this sector. Additionally, a stainless steel wire cable tray’s easy maintenance ensures longevity, reducing downtime in high-output environments.

Pharmaceutical: Precision and Cleanliness Above All

In pharmaceutical manufacturing, cleanliness isn’t just a preference; it’s a mandate. The sleek, smooth finish of stainless steel cable trays makes them easy to clean and maintain, ensuring no contaminants compromise the sterile environment.

Pharma facilities often prefer a wire mesh cable tray or basket for cables for their lightweight design and superior airflow. This helps organize complex cabling networks for HVAC systems, automated production lines, and laboratory equipment.

Food and Beverage Processing: Meeting Hygiene Standards

Picture a bustling food processing facility, where precision, hygiene, and efficiency are paramount. Here, a stainless steel cable basket plays a vital role. It resists moisture, doesn’t rust, and meets strict sanitation standards, making it perfect for routing cables in damp or food-prep areas.

From conveyors to refrigeration units, flexible cable trays ensure that wiring remains protected and easy to access for maintenance, reducing downtime in this fast-paced industry.

Construction: Commercial and Residential Projects

The construction industry is no stranger to the versatility of cable tray systems. From high-rise office buildings to sprawling residential complexes, these stainless steel cable baskets simplify cable routing during installation.

For projects requiring aesthetic solutions, a ceiling cable tray or floor cable tray offers organized cable management while keeping wires out of sight. Whether for power lines, IT networks, or security systems, these trays provide a neat, professional finish to modern construction.

Telecommunication: Supporting Digital Connectivity

Telecommunication networks thrive on precision and uptime. In data centers and server rooms, a stainless steel wire basket tray is invaluable for organizing Ethernet and fiber optic cables. cable duct stainless steel’s open design allows maximum ventilation, reducing heat buildup that could disrupt data transmission.

A desk cable organizer tray or cable management desk tray is often used in office setups to maintain neatness and functionality, ensuring seamless communication in today’s connected world.

Water Treatment Plants: Managing Critical Operations

Water treatment facilities deal with a mix of electrical and mechanical systems that must be meticulously organized. Here, a galvanized steel cable tray provides corrosion resistance while securely supporting critical wiring.

For underground or wet environments, a cable tray galvanized steel option is commonly employed, ensuring durability and long-term reliability in challenging conditions.

Mining: Withstanding Rugged Environments

Mining operations demand equipment that can endure dust, debris, and heavy vibrations. A heavy-duty stainless steel cable tray is the perfect fit for organizing the robust electrical systems that power drills, conveyor belts, and safety equipment.

Additionally, cable racking is used in mines to manage extensive wiring networks, ensuring safety and efficiency in one of the toughest industries.

Automotive and Aerospace: Driving Innovation

In industries where precision meets performance, such as automotive and aerospace, cable management takes on a whole new level of importance. A stainless steel cable tray supports the intricate wiring systems required for advanced manufacturing robotics and assembly lines.

For these applications, mesh wire trays and flex cable trays offer flexibility and easy access, allowing engineers to adapt and upgrade cabling systems as technology evolves.

The Role of Stainless Steel Cable Tray Manufacturers

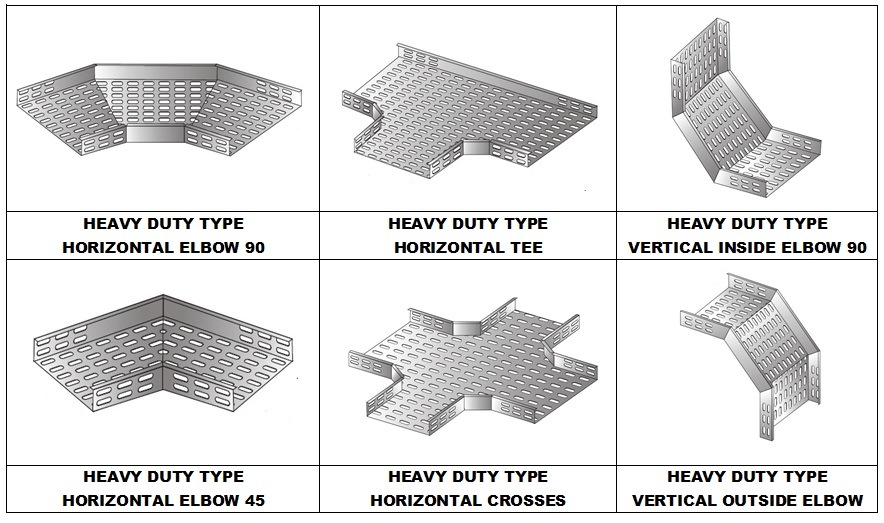

Behind the scenes, stainless steel cable tray manufacturers play a pivotal role in delivering tailored solutions for these diverse industries. By offering a range of designs—like ladder trays, metal cable trunks, and wire mesh trays—they ensure businesses get the right fit of stainless steel cable basket for their unique needs.

Partnering with a trusted manufacturer guarantees compliance with industry standards, durable products, and ongoing support to optimize cable management systems across various sectors.

Conclusion

The stainless steel cable tray is a silent yet essential player in the success of industries ranging from power generation to food processing. Its durability, resistance to environmental challenges, and adaptability make it a preferred choice across the globe.

Whether you’re managing miles of cables in a power plant or organizing Ethernet cords in a data center, a well-chosen cable tray ensures efficiency, safety, and peace of mind. By understanding how different industries utilize these trays, you can better appreciate their versatility and importance in keeping the world’s systems running smoothly.

- Which Steel Cable Tray Type is Best? A Look at Perforated, Ladder, Wire Mesh & Flexible Trays

- The Impact of Temperature Variations on Cold Storage Warehouses in Different Cities of Uganda

- Uganda’s Rising Demand for Cold Storage Builders in the Logistics Industry

- The Impact of Factory Shed Layout on Workflow Efficiency

- Custom Window Fabrication: Different Types, Applications, Benefits for Residential and Commercial Spaces